Plastic Bottle Suppliers Fundamentals Explained

Table of ContentsThe 7-Second Trick For Plastic Bottle Suppliers4 Easy Facts About Plastic Bottle Suppliers DescribedThe Basic Principles Of Plastic Bottle Suppliers 7 Simple Techniques For Plastic Bottle SuppliersMore About Plastic Bottle Suppliers

When the polymer product has actually cooled down sufficient to set, the mould is opened up and also the container caps are expelled. If a number of caps are being made from a solitary mould (as is often the case), they will be very carefully divided from each other as well as get ready for additional handling (e - plastic bottle suppliers. g., wadding, securing).Shot moulding is one of the most usual production approach for container caps for numerous excellent reasons. For example, injection moulding is extremely price reliable for huge manufacturing runs. It likewise displays high repeatability, which implies there will be virtually no variant in measurement, form, or surface area finish from cap to cap or perhaps batch to set.

The moulds made use of support high degrees of information and also make it simple for premium quality embossing to be added (which will certainly be talked about even more on in a separate area). Injection mould made use of for making numerous bottle caps. The moulds themselves are frequently painstakingly machined from durable stainless-steel as well as used hundreds of times in a single manufacturing run.

About Plastic Bottle Suppliers

When it comes to container caps, the moulds themselves contain the inverse form of the container cap, consisting of the strings and also whatever will certainly be embossed on the top and/or sides of the cap. It is necessary that these style details remain dimensionally stable as the part cools down in the mould, and also the mould has to be designed so that the part cools down equally within the mould to avoid distortion of the final shape.

Moulds are pricey for container caps as a result of the intricacy included in accomplishing the internal thread, which are considered undercut components and also entail special mould design factors to consider and also tooling to ensure that the components can be gotten rid of after cooling down without damage. Nonetheless, when a making business has currently bought high top quality, facility moulds for typical container cap sizes and threading, certain minimal amounts can be made.

In reality, this choice can actually get rid of the need for a label and can consist of cross advertising or item cautions. Extremely described embossed plastic bottle caps that consist of a firm logo and also message. Embossing additionally acts as a terrific way to attract the interest of consumers or users that could tend to ignore a label but can not ignore the lid while they are opening the container, specifically when embossing is incorporated with custom-made colours.

Due to exactly how easy it is to consist of embossing in the bottle cap manufacturing procedure, there is typically no additional cost. The lining material between the bottle cap as well as the has of the container is called an and also can serve different functions. It can act as a seal to protect the stability of the materials, protecting them from wetness or oxygen.

Our Plastic Bottle Suppliers PDFs

Or a wad can make it obvious if a person has actually tampered with the materials and also when it comes to a product such as medication, evidence of meddling can protect against somebody from ingesting something that might make them unwell or maybe poisonous substance them. Beyond selecting a wad based on the function it have to serve, it is also key to bear in mind that the heap product dealing with the container should be chemically compatible with the materials of the container.

, or, are polycell heaps that have a layer of aluminum foil included in protect the polywad from any kind of chemicals in the container and support chemical compatibility. consist of a layer of foil with wax-like substance with an extremely reduced melting point on the side toward the container and its contents.

Before the procedure starts, the container cap is connected to the container at a particular torque. Next off, the container and also cap are passed beneath an oscillating electromagnetic field. When that magnetic field takes a trip via the air and experiences the steel surface area of the aluminum foil, a knockout post a high oscillating electric existing is generated in the foil.

The Basic Principles Of Plastic Bottle Suppliers

The whole securing procedure is accomplished without the requirement for anything to touch either the bottle or the cap except for moving browse around this site them underneath the electro-magnetic area. Only the metal aluminum foil is warmed, and also after that only enough to thaw the wax-like compound, so the components within the container (and the container/cap itself) continue to be totally unmodified and also unaffected during the procedure. plastic bottle suppliers.

This produces a powerful obstacle to both wetness and oxygen that functions well for items in powder or liquid kind. There is an impressive quantity of detail simply in the layout of a container cap, with the threading, dimensions, and also option of wadding and embossing. When the recyclable plastic and customized colour has actually been chosen, it is injection molded under incredibly high stress to create a high top quality bottle cap from a complex mould.

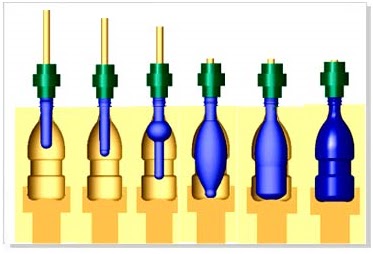

PROJECT RECORD Address The global plastics sector is observing a constant change of production bases to affordable Asian nations. With enhancing international investment and also rise in the variety of new manufacturing facilities in the region, Asia has actually become the biggest and also the fastest growing market for plastics in the globe. The mold contains a core side and a cavity side that is placed into a plastic shot molding maker. This browse around this web-site equipment heats the raw plastic resin pellets till they're thawed, infuses them into the empty dental caries of the mold and mildew under fantastic pressure, and afterwards available to expel the completed component.

Molds however can be expensive as well as complicated, depending on the component geometry. Mindful engineering layout of the mold is needed to avoid flaws and also maximize part quality and also handling rate. Rotational molding also uses a core as well as dental caries mold and mildew device, but the production procedure is fairly various. Plastic powder is put right into the cavity of the mold, and also the mold and mildew placed in an oven.

Rumored Buzz on Plastic Bottle Suppliers

Gravity is used to stick the plastic to the tool wall surfaces and also develop the proper density. After that, the mold and mildew is eliminated from the oven and gradually cooled down to stop warpage. plastic bottle suppliers. Full cooling can take a number of mins, after which the tool is opened and also the part removed for the following cycle.

The finished parts are hassle-free and have no joints so they're solid, and the devices are relatively simple and low-cost to make. The downside is that devices don't last greater than a couple of thousand cycles before they require to be replaced, and also the component complete top quality is typical at best so it's not suited for accuracy developing.