The smart Trick of Alcast Company That Nobody is Talking About

Table of ContentsWhat Does Alcast Company Mean?7 Easy Facts About Alcast Company ShownAlcast Company - An Overview7 Easy Facts About Alcast Company ExplainedThe Of Alcast CompanyAlcast Company - Truths

Chemical Comparison of Cast Aluminum Alloys Silicon promotes castability by lowering the alloy's melting temperature level and boosting fluidness during spreading. In addition, silicon contributes to the alloy's toughness and use resistance, making it important in applications where resilience is essential, such as automotive parts and engine components.It also improves the machinability of the alloy, making it less complicated to refine right into finished items. In this way, iron contributes to the general workability of aluminum alloys.

Manganese adds to the toughness of aluminum alloys and enhances workability (Foundry). It is typically made use of in functioned aluminum items like sheets, extrusions, and profiles. The presence of manganese aids in the alloy's formability and resistance to breaking throughout manufacture processes. Magnesium is a light-weight aspect that provides stamina and influence resistance to aluminum alloys.

The Ultimate Guide To Alcast Company

It permits the manufacturing of light-weight elements with outstanding mechanical residential or commercial properties. Zinc enhances the castability of light weight aluminum alloys and helps manage the solidification process during spreading. It improves the alloy's strength and hardness. It is often discovered in applications where complex forms and great information are essential, such as decorative castings and particular auto parts.

The main thermal conductivity, tensile strength, return stamina, and elongation differ. Among the above alloys, A356 has the highest possible thermal conductivity, and A380 and ADC12 have the most affordable.

Things about Alcast Company

In accuracy casting, 6063 is appropriate for applications where intricate geometries and high-quality surface area coatings are extremely important. Instances include telecommunication rooms, where the alloy's premium formability permits for smooth and aesthetically pleasing styles while keeping architectural honesty. In the Illumination Solutions industry, precision-cast 6063 elements develop elegant and effective lights fixtures that need detailed shapes and excellent thermal performance.

The A360 shows superior prolongation, making it optimal for complicated and thin-walled elements. In precision casting applications, A360 is fit for sectors such as Customer Electronic Devices, Telecommunication, and Power Devices.

Examine This Report on Alcast Company

Its one-of-a-kind residential properties make A360 an important option for accuracy spreading in these markets, boosting product resilience and top quality. Light weight aluminum alloy 380, or A380, is a commonly made use of spreading alloy with numerous distinct attributes. It provides outstanding castability, making it an excellent choice for accuracy casting. A380 exhibits great fluidness when molten, making sure detailed and in-depth mold and mildews are accurately reproduced.

In precision spreading, light weight aluminum 413 radiates in the Customer Electronics and Power Devices markets. This alloy's exceptional corrosion resistance makes it a superb option for outside applications, making sure durable, resilient items in the pointed out markets.

The 5-Minute Rule for Alcast Company

As soon as you have chosen that the aluminum die casting procedure is suitable for your project, an essential next action is selecting the most ideal alloy. The light weight aluminum alloy you select will significantly impact both Get the facts the spreading process and the residential or commercial properties of the final item. Since of this, you must make your decision meticulously and take an enlightened approach.

Figuring out the most ideal aluminum alloy for your application will certainly imply evaluating a vast range of attributes. The first category addresses alloy attributes that impact the production process.

A Biased View of Alcast Company

The alloy you select for die casting directly impacts a number of facets of the spreading procedure, like exactly how easy the alloy is to collaborate with and if it is prone to casting issues. Warm splitting, also recognized as solidification cracking, is a typical die casting defect for aluminum alloys that can lead to inner or surface-level rips or splits.

Certain light weight aluminum alloys are extra at risk to warm fracturing than others, and your selection ought to consider this. An additional usual flaw located in the die spreading of light weight aluminum is pass away soldering, which is when the cast adheres to the die walls and makes ejection tough. It can damage both the cast and the die, so you need to seek alloys with high anti-soldering properties.

Deterioration resistance, which is already a noteworthy feature of light weight aluminum, can differ considerably from alloy to alloy and is a necessary characteristic to think about depending on the environmental conditions your item will be exposed to (aluminum casting company). Use resistance is another property generally looked for in light weight aluminum items and can distinguish some alloys

Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Nancy McKeon Then & Now!

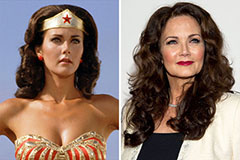

Nancy McKeon Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!